APCS Analiq

Portable levelmeter–analyzer of liquids ANALIQ-M

Portable levelmeters and analyzers of liquids ANALIQ-M are designed for real-time measurements of level, temperature, density, type and weight of liquids, including those that are hazardous to health or stored under pressure. The analysis can be performed without opening the containers with liquids or stopping the technological process.

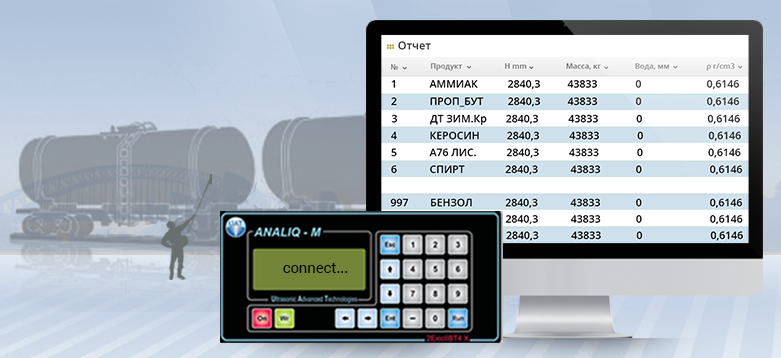

The device is supplied with software ANALIQ for data exchange with a computer.

-

Main features

-

Application

-

Technical characteristics

-

Operating features

-

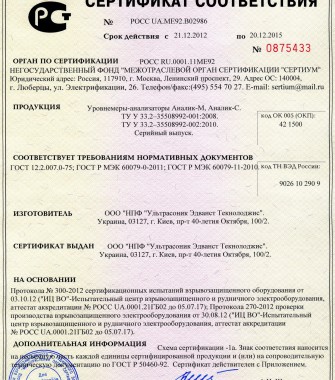

Certificates

- No contact with the internal medium of a container

- Possible to use for measurement through the tank wall thickness up to 50 mm

- Measures of not only level and volume, but also density, type and weight of the liquid

- Measurement of LPG percentage of propane/butane, vapor pressure and mass

- Low power consumption - continuous operation time up to 200 hours using 8 AA batteries

- Explosion-proof

- Memory sufficient for 999 measurements

- Efficiency and ease of use

ANALIQ-Mis successfully used by oil traders, militarized guard, fire-insurance companies, customs services and other companies involved in transportation, maintenance and protection, for:

- Commercial accounting of petroleum products, LPG in railway (or auto) tanks, cylinders and containers

- Identification of inconsistencies of the types of fluids declared in the invoice

- Measurement of the level of underproduct or overproduct water

Using this device it is possible to measure a whole railway train transporting oil products within 40-50 minutes on any section of the route, including those trains connected to contact mains, without opening the tank or performing in-laboratory analysis.

- Magnetic method of antenna and temperature sensor attachment

- Thickness of the reservoir walls, through which the device is able to operate - 0-50 mm

- The range of measured levels – 30-50000 mm

- The instrument error: +/- 1 mm within an interval of 100-5000 mm

- Continuous operation time up to 200 hours (8 * AA)

- Explosion proof label - PA and PT - "0EhіsIIBT4 X"

- Operating temperature : measuring unit (-30-+50 OС) , sensors (-50-+50 OС) -50- + 50 OС

- Degree of protection IP54 / IP65

- Unit dimensions - (155x130x75) mm

Working with the levelmeter and analyzer consists of two stages:

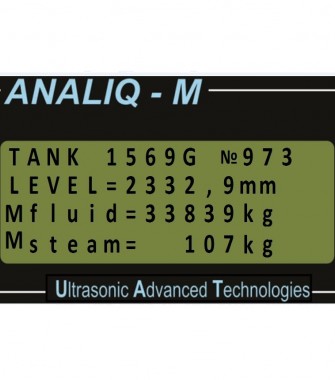

Measurement №1 (calibration) - the results of this measurement are as follows: the value of speed of sound propagation in this liquid, type of liquid and its density at the current temperature.

Measurement №2 - the measurement result are:

The fluid level, the presence of underproduct water, the volume and mass of the analyzed liquid.

For a mixture of propane/butane the ratio of its components, pressure, density and vapor mass are defined additionally.

Measurement time is 3-5 seconds.

To maintain high measurement accuracy it is necessary to perform the measurement on both left and right sides of a tank. Averaging the results eliminates an error resulting from the non-horizontal position of a reservoir (tank).

The features of carrying out the measurements of vertical reservoirs that do not provide access to the bottom part, is somewhat different from the order of measurement of horizontal tanks – the measurement of level is performed through a flange welded pipe.

One measurement cycle, including the site preparation for temperature sensor and antenna, their installation, calibration, and the level measurement itself do not exceed 1-1.5 minutes per tank (reservoir).

The energy – independent memory of the levelmeter and analyzer stores:

— more than 60 calibration tables, including those for virtually all types of railway tanks used in the former CIS.

— Data on the properties for more than 40 types of liquids.The "knowledge base" of the device can be extended more than twice.