APCS Analiq

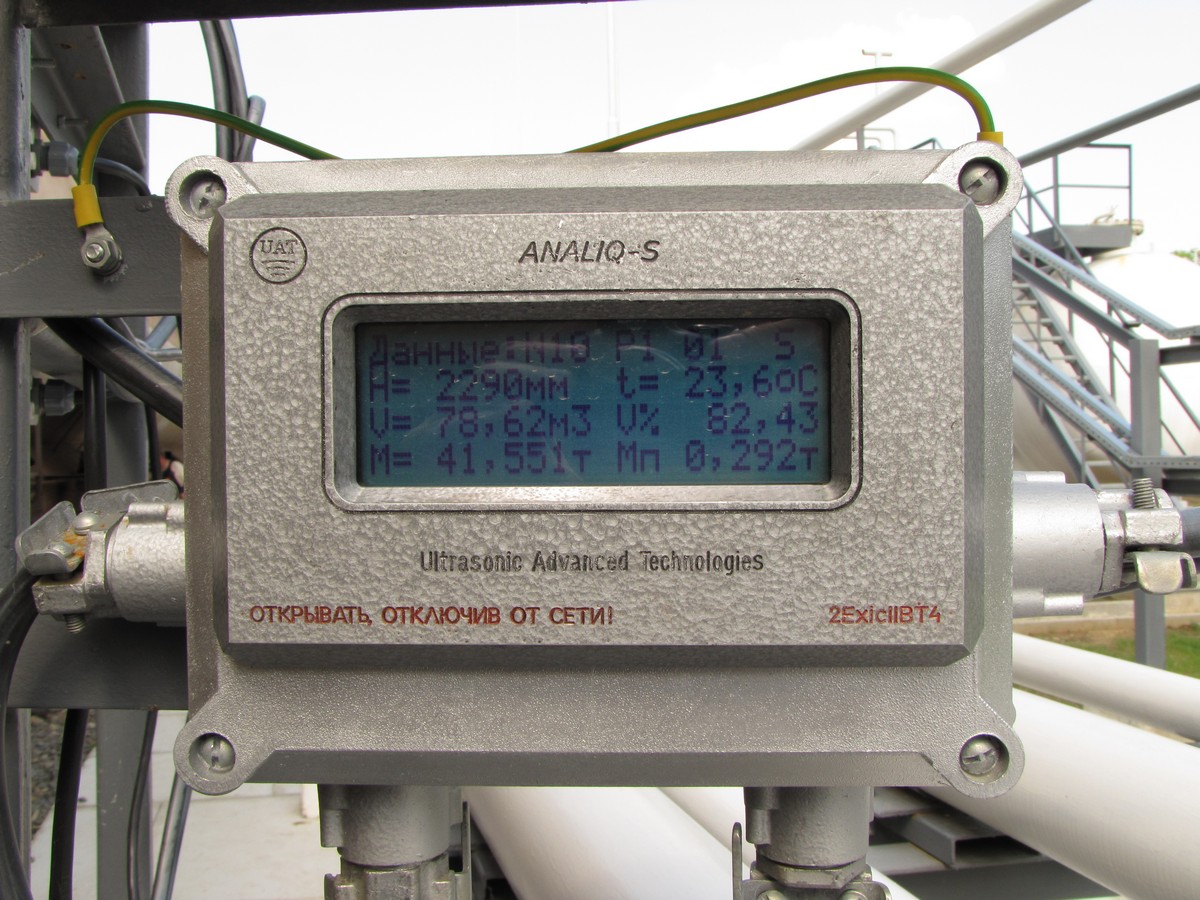

Stationary levelmeter - analyzer of liquids ANALIQ-S

Stationary levelmeter and analyzer of liquids ANALIQ-S is installed on each tank of a storage park, LPG filling station, technological reservoir for reloading of oil products. It provides continuous measurement of level, temperature, density, determination of volume and other parameters of liquids. Measurement data and alarm signals are transmitted to a computer, wireless microcontroller or other devices APCS

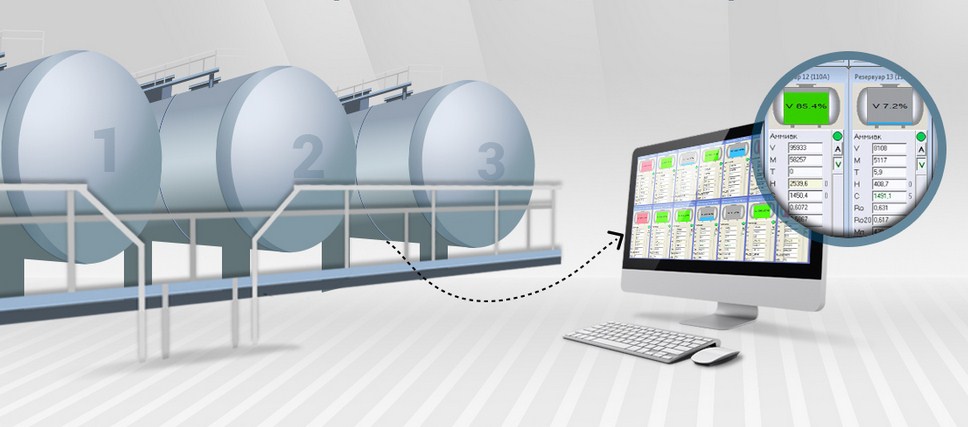

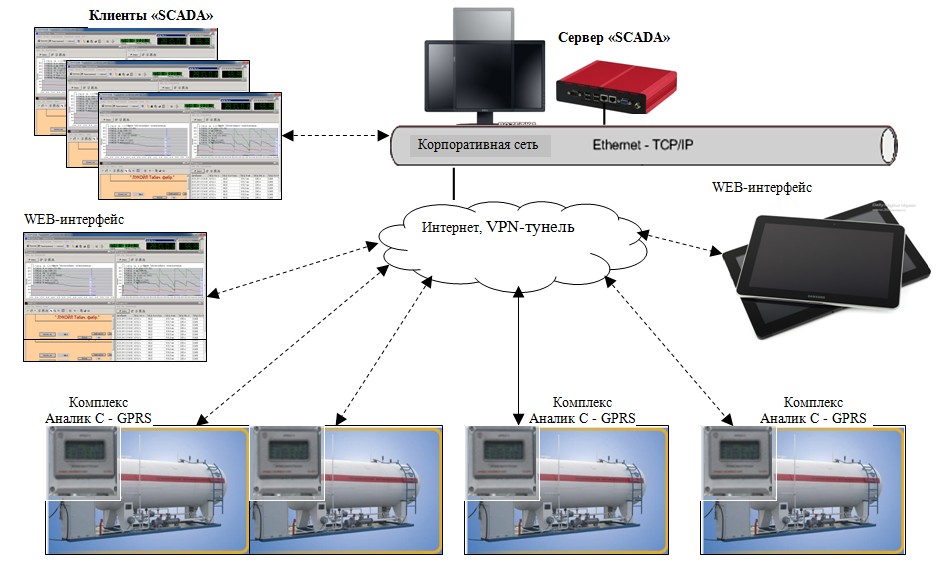

ANALIQ-S levelmeter may in some cases replace or duplicate level sensors. Software ANALIQ-MS was developed to create an automated process control systems for loading and safe storage of petroleum products and other liquids. It provides continuous survey of instruments, convenient visualization of the process on a computer screen, formation of warning and alarm signals when limit levels are achieved, data transmission to automated systems of commercial or technical accounting and other SCADA-systems, alarm systems, remote monitoring systems.